spieth10@spiethstorage.com

spieth10@spiethstorage.com +8615259233328

+8615259233328

-

Tel : +8615259233328

Tel : +8615259233328

-

E-mail : spieth10@spiethstorage.com

E-mail : spieth10@spiethstorage.com

-

Address : Tongan Park, Tongan District, Xiamen, China 361023

Address : Tongan Park, Tongan District, Xiamen, China 361023

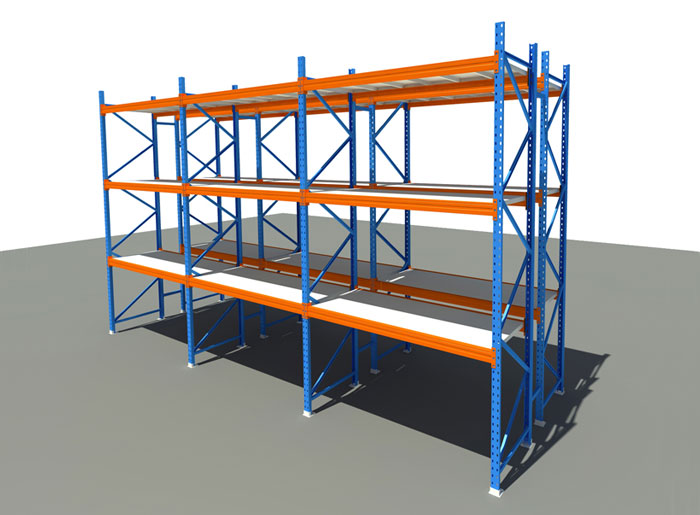

Heavy Duty Drive In Pallet Racking Systems for Warehouse Storage

Drive In Pallet Racking Description:

Spieth drive in pallet racks are a cost-effective solution to high-density storage. This static system has rails running the depth of the rack for pallet placement. The only limitation to the depth of pallet storage is the capability to drive deep within the system. The rack depth reduces the need for aisles and drastically increases cubed space utilization.

This type of installation is made up of a set of racking units that form inner loading aisles,with support rails for the pallets.The forklift trucks enter these inner aisles with their load held higher than the level at which it is to be deposited.

Each loading aisle has support rails on both sides.These are arranged on different levels and the pallets are placed on top. This racking system is made of extremely robust material,thus making it suitable for storing fully-loaded pallets.

Features:

- Most cost-effective high-density storage rack

- Excellent solution for large volume storage of like product

- May be able to use existing forklift equipment

- Allows for use of either roll-formed or structural rack materials

- Forklift has straight access to product loads, allowing for deeper pallet storage

- Drive In is a LIFO (last in, first out) storage system

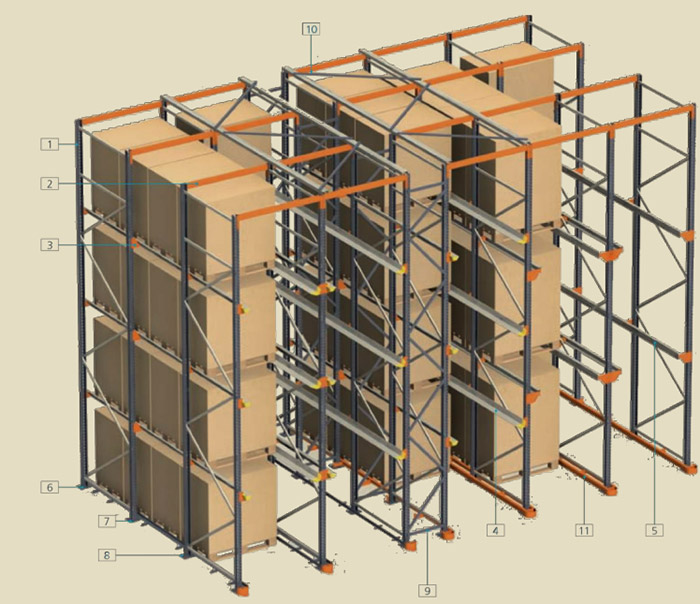

Drive In Pallet Racking Main Structure:

1. Frame

2. Drive-in beam

3. Bracket

4. GP-7 rail

5. C-rail

6. Upright footplate

7. Levelling plates

8. Anchor bolts

9. Bracing set (Construction system 1)

10. Upper cross bracing (Construction system 2)

11. Guide rail (optional)

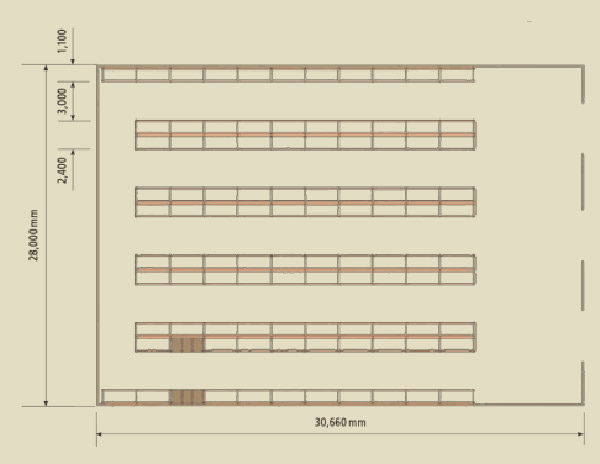

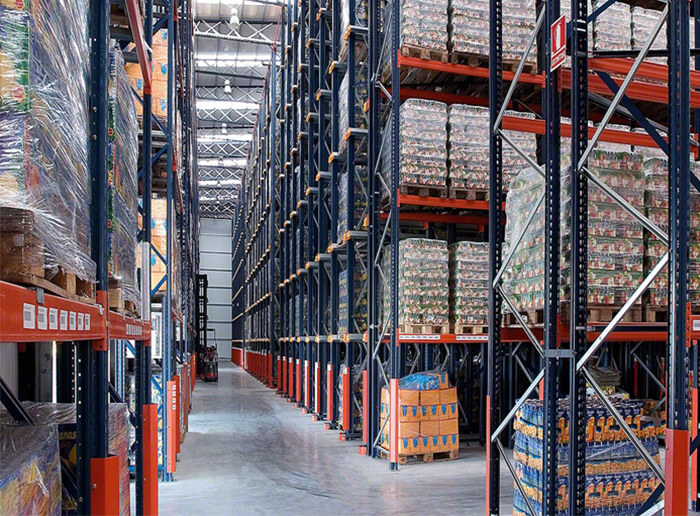

Conventional distribution

Total area for atorage: 858m2

Capacity: 306 pallets per level

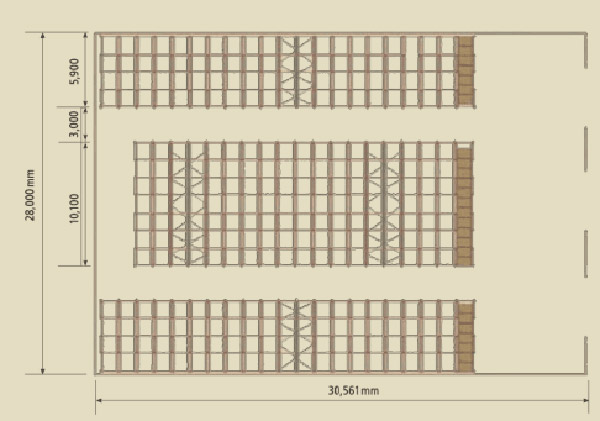

Drive-in distribution

Total area for storage: 855m2

Capacity: 522 pallets per level

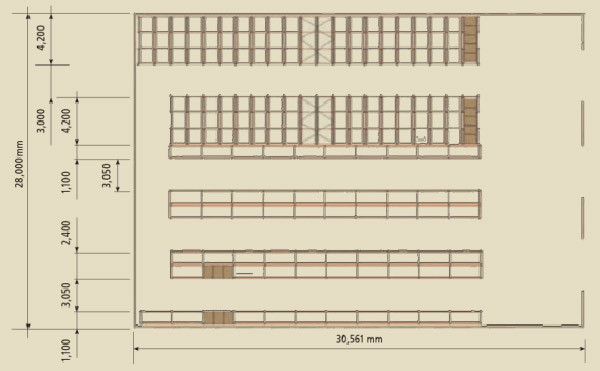

Capacity: 383 pallets per level (200 pallets

on drive-in system and 183 pallets on

conventional pallet racking)

Product Cases:

-

Do you offer samples available?Yes, samples are available. Sample lead time 3-5days generally.

-

Do you offer custom design?Custom design is surely available. we have very rich experience in customizing shelves.

-

What is the term of payment?Regularly, 30percentTT in advance,70percent against the copy of B/L.

-

What is your delivery time?Usually: 1*20' GP container, around 15 days; 1*40'GP container, around 20days; For some urgent orders,will adjust as your requirement accordingly.

-

Are you manufacturer or trading company?We are manufacturer. Our factory has been specializing in warehouse storage equipments for years. We warmly welcome you to visit our factory at anytime.

-

-

+8615259233328

+8615259233328

0

0

Link:

Link: