spieth10@spiethstorage.com

spieth10@spiethstorage.com +8615259233328

+8615259233328

CATEGORIES

NEW PRODUCTS

CONTACT US

-

Tel : +8615259233328

Tel : +8615259233328

-

E-mail : spieth10@spiethstorage.com

E-mail : spieth10@spiethstorage.com

-

Address : Tongan Park, Tongan District, Xiamen, China 361023

Address : Tongan Park, Tongan District, Xiamen, China 361023

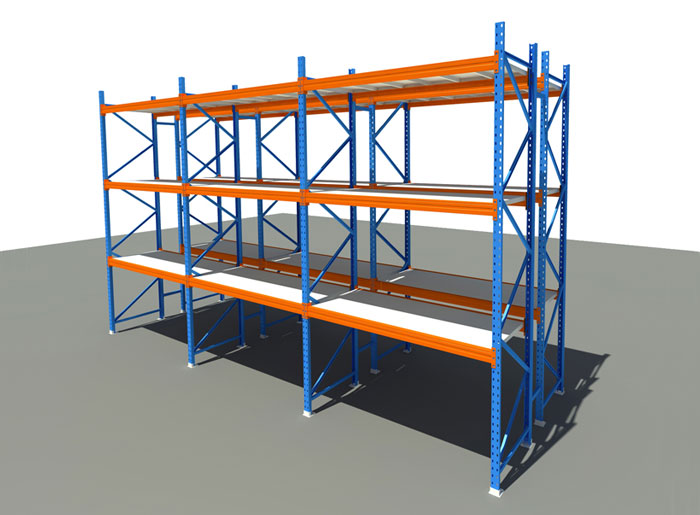

Drive in Racking for Cold Storage

Item NO.: Drive in Rack-01

Drive in pallet racking system has good storage density,suitable for material warehouse or cycle warehouse with high efficiency or timely operation.

DESCRIPTION

FAQ

The drive in rack system is a high-density storage solution for warehouses storing pallets on a first-in/last-out (FILO) basis. Drive in pallet racks are ideal for high volumes of identical or limited SKUs. It is a last-in, first-out (LIFO) storage racking system with a single channel that enables deep compression designs. The drive in rack creates a cost-effective, high-density storage system that allows deep storage of pallets in multiple locations, reducing the space required in aisles.

The china drive-in racking is easy to identify by its unique storage lanes equipped with horizontal rails that run the full depth of the rack. Pallets are loaded and retrieved from the front side of the rack and forklift trucks drive directly into the rack's bays to get to the stored product. The last pallet loaded becomes the first pallet accessible, creating a more dense and uniform load in a confined storage area. The system can store up to 10+ pallets deep per lane.

The china drive-in racking is easy to identify by its unique storage lanes equipped with horizontal rails that run the full depth of the rack. Pallets are loaded and retrieved from the front side of the rack and forklift trucks drive directly into the rack's bays to get to the stored product. The last pallet loaded becomes the first pallet accessible, creating a more dense and uniform load in a confined storage area. The system can store up to 10+ pallets deep per lane.

Pallets are loaded onto horizontal rails. Drivers then remove the pallets from the same entry point at which they were loaded. Drive-in rack systems are often used against a wall. Drive in racking systems are based on the same concept but are located in an open area so that forklifts can drive completely through the rack system.

Advantages of Drive-in Racking

Pallets are loaded onto horizontal rails. Drivers then remove the pallets from the same entry point at which they were loaded. Drive-in rack systems are often used against a wall. Drive in racking systems are based on the same concept but are located in an open area so that forklifts can drive completely through the rack system.

Advantages of Drive-in Racking

- Custom-designed for your pallets & forklifts

- Maximum pallet storage

- Lane depth 10+ pallets deep

- Space saver, low-profile arms

- Virtually unlimited depth of storage

- Cost-effective storage strategy

- Welded aisle-side load arms and rail stops

- Ideal for high-volume, low-SKU applications

- Flared rail entry ends allow easy bay access

- Load rails constructed of durable structural angle steel

- Limited aisles, resulting in more efficient use of space

-

Do you offer samples available?Yes, samples are available. Sample lead time 3-5days generally.

-

Do you offer custom design?Custom design is surely available. we have very rich experience in customizing shelves.

-

What is the term of payment?Regularly, 30percentTT in advance,70percent against the copy of B/L.

-

What is your delivery time?Usually: 1*20' GP container, around 15 days; 1*40'GP container, around 20days; For some urgent orders,will adjust as your requirement accordingly.

-

Are you manufacturer or trading company?We are manufacturer. Our factory has been specializing in warehouse storage equipments for years. We warmly welcome you to visit our factory at anytime.

Send Message

Please leave your email address to get the catalogue & price list!

Subject: Drive in Racking for Cold Storage

ONLINE SERVICE

-

-

+8615259233328

+8615259233328

0

0

Browsing History

Link:

Link: